Introduction

Puff print and silk screen print are two different methods of printing used primarily in the textile and fashion industry. Although they share some similarities, they have distinct characteristics and applications. In this explanation, we will explore the differences between the two printing methods, covering aspects such as technology, fabric compatibility, print quality, durability, and more.

1. Technology:

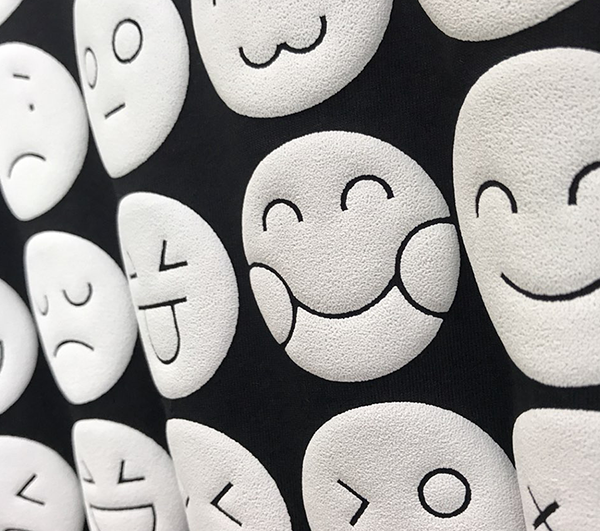

Puff print: Puff print technology involves applying heat and pressure to transfer ink onto the fabric, resulting in a raised, three-dimensional print. It is commonly used for printing on polyester and other synthetic fibers. The process involves heat-activated inks, which expand and bond with the fabric when exposed to heat and pressure.

Silk screen print: Silk screen printing, also known as screen printing, is a manual or automated process that involves passing ink through a mesh screen onto the fabric. It is commonly used for printing on cotton, polyester, and other natural and synthetic fibers. The process involves creating a stencil on a mesh screen, which allows ink to pass through only in the desired pattern.

2. Ink Application:

Puff print: In Puff Print, the ink is applied using a squeegee or roller, which pushes the ink through a mesh screen onto the fabric. This creates a raised, three-dimensional effect on the fabric.

Silk screen print: In Silk Screen Print, the ink is also pushed through a mesh screen, but it is applied more evenly and does not create a raised effect. Instead, it creates a flat, two-dimensional design on the fabric.

3. Stencil:

Puff print: In Puff Print, a thicker, more durable stencil is required to withstand the pressure of the squeegee or roller pushing the ink through the mesh screen. This stencil is typically made of materials like mylar or polyester, which can withstand the pressure and wear and tear of repeated use.

Silk screen print: Silk Screen Print requires a thinner, more flexible stencil, which is typically made of materials like silk or polyester mesh. This allows for more intricate designs and greater control over the ink application.

4. Ink Type:

Puff print: In Puff Print, a plastisol ink is typically used, which is a type of plastic ink that has a soft, rubbery texture. This ink is able to conform to the raised surface of the fabric, creating a smooth, even finish.

Silk screen print: Silk Screen Print uses a water-based ink, which is more fluid and can be printed onto fabric in a more precise manner.

5. Process:

Puff print: Puff Print is a hand-crafted technique that involves using a special tool called a puffer or sponge to apply ink onto a substrate. The puffer is dipped into a container of ink, which can be water-based or solvent-based, and then pressed onto the material. The ink is absorbed by the fibers of the fabric, creating a raised, 3D effect. Puff Printing requires skilled artisans who can control the amount of ink and pressure applied to create consistent and detailed designs.

Silk screen print: Silk Screen Printing, on the other hand, is a more industrialized method that uses a stencil to transfer ink onto a substrate. The stencil is made of a fine mesh screen that is coated with a photosensitive emulsion. The design is drawn onto the screen using a special film called a stencil master. The screen is then exposed to light, hardening the emulsion where the design is drawn. The screen is then washed out, leaving behind a solid area where the emulsion was hardened. This creates a negative image of the design on the screen. Ink is then pushed through the open areas of the screen onto the substrate, creating a positive image of the design. Silk Screen Printing can be done by machine or by hand, depending on the complexity of the design and the desired outcome.

6. Printing Speed:

Puff print: Puff Print is generally slower than Silk Screen Print, as it requires more time and effort to apply the ink evenly and create a raised effect on the fabric.

Silk screen print: Silk Screen Print, on the other hand, can be faster because it allows for more precise control over the ink application and can be used to print larger designs more quickly.

7. Fabric compatibility:

Puff print: Puff print is suitable for synthetic fibers like polyester, nylon, and acrylic, as they tend to retain heat and create a puffed effect when heated. It is not ideal for printing on natural fibers like cotton and linen, as they tend to wrinkle or burn when exposed to high heat.

Silk screen print: Silk screen printing can be done on a wide range of fabrics, including natural fibers like cotton, linen, and silk, as well as synthetic fibers like polyester, nylon, and acrylic. The fabric's porosity, thickness, and stretchiness should be taken into consideration when choosing the ink and printing process.

8. Print quality:

Puff print: Puff print offers high print quality with sharp images and vivid colors. The three-dimensional effect makes the print stand out, giving it a unique and luxurious feel. However, the process may not be as detailed as silk screen printing, and some finer details may be lost.

Silk screen print: Silk screen printing allows for greater detail and variety in the prints. The process can create intricate patterns, gradients, and photographic images with high accuracy. Colors are usually vibrant, and the prints are durable.

9. Durability:

Puff print: Puff Print is known for its high durability, as the raised surface of the ink creates a thicker layer of ink that is less likely to crack or peel over time. This makes it ideal for items like t-shirts, bags, and other items that will be subjected to regular wear and tear. The heat-activated inks used in puff printing are generally wash-resistant and durable. The three-dimensional print adds a degree of texture to the fabric, making it more resistant to wear and tear. However, the print may fade or pill with extended exposure to sunlight or harsh chemicals.

Silk screen print: Silk screen prints are known for their durability, as the ink bonds with the fabric fibers. The prints can withstand frequent washing and drying without fading or losing their vibrancy. It can be used for items like posters, banners, and other items. However, like puff print, they may pill or fade with extended exposure to sunlight or harsh chemicals.

10. Environmental impact:

Puff print: The process of puff printing involves the use of heat and pressure, which can consume energy and generate waste. However, modern equipment and techniques have improved energy efficiency, and some puff print machines now use eco-friendly inks that are less harmful to the environment.

Silk screen print: Silk screen printing also requires the use of ink, which can be potentially harmful to the environment if not properly managed. Some manufacturers now offer eco-friendly ink options that are less toxic and more sustainable. Additionally, the process does not involve heat or pressure, reducing energy consumption.

11. Cost:

Puff print: Puff Print can be more expensive than Silk Screen Print, as it requires more materials and labor to create the raised effect on the fabric. Additionally, Puff Print machines are typically larger and more complex than those used for Silk Screen Printing, which can also increase costs. Puff printing is generally more expensive than silk screen printing due to the specialized equipment and materials required. The three-dimensional effect also requires more time and energy to produce, which can drive up costs.

Silk screen print: Silk screen printing is known for its cost-effectiveness, as the equipment and materials are relatively affordable and it requires fewer materials and can be done more quickly. The process is also faster and more efficient than puff printing, leading to lower production costs. However, the cost can vary depending on factors like the size of the design, the number of colors used, and the complexity of the design.

12. Applications:

Puff print: Puff printing is commonly used in the fashion industry for printing on clothing, accessories, and home decor items. It is often used for creating custom designs for individual customers or small businesses that want to add a unique touch to their products. Puff Printing is also used in the fashion industry for creating one-of-a-kind garments and accessories that showcase the artist's creativity and skill.

Silk screen print: Silk Screen Printing, on the other hand, is widely used in various industries for mass production of printed goods, including fashion, textile, and promotional products. It is commonly used for printing logos, text, and graphics on T-shirts, hats, bags, towels, and other items. Silk Screen Printing is ideal for businesses that need to produce large quantities of printed products quickly and efficiently. It is also used in the fashion industry for creating prints on fabrics and garments that can be sold at retail stores.

13. Appearance:

Puff print: Puff Printing creates a raised, 3D effect that adds dimension and texture to the design. The ink is absorbed by the fibers of the fabric, creating a unique look that cannot be achieved with other printing methods. Puff Printing is ideal for creating bold, eye-catching designs with intricate details and textures.

Silk screen print: Silk Screen Printing, on the other hand, creates a flat, smooth appearance on the substrate. The ink is transferred through the open areas of the screen, creating sharp lines and clear images. Silk Screen Printing is ideal for creating large quantities of consistent, high-quality prints with minimal effort. It is commonly used for printing logos, text, and simple graphics on T-shirts, bags, and other items.

Conclusion

In conclusion, both puff print and silk screen print have their advantages and limitations. The choice between the two printing methods depends on factors such as fabric type, print quality, durability, budget, environmental concerns and so on. Understanding the differences between the two printing methods helps designers and manufacturers make informed decisions for their projects.

Post time: Nov-28-2023